Safety and productivity are two cornerstones of operational success. From large-scale warehouses to manufacturing facilities and distribution centers, businesses must look for ways to optimize operations while maintaining a safe work environment. One transformative solution gaining traction is the adoption of intelligent lighting systems. These systems, made of energy-efficient LED lighting technology and smart controls, offer a range of benefits that defy expectations. By improving visibility, reducing energy consumption, and enabling advanced automation, intelligent lighting solutions are revolutionizing how industrial spaces operate.

Improving Safety with Intelligent Lighting

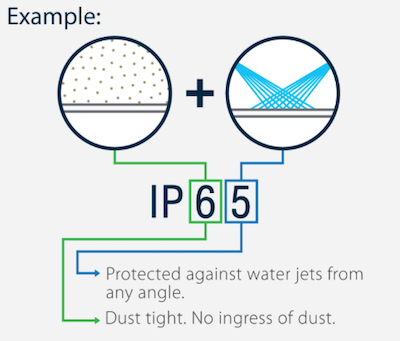

A well-lit workplace is a safer workplace. In industrial facilities, poor lighting is often a significant contributor to workplace accidents. Whether it’s navigating large equipment, handling hazardous materials, or managing intricate assembly lines, visibility is critical for minimizing risk. Intelligent lighting systems enhance safety through several key features:

- No Dark Spots

Traditional lighting solutions can sometimes fall short. Whether that be through uneven lighting coverage or burnt out bulbs, these shadows and dark spots can create potential hazards. Intelligent LED lighting alerts you when there are dark spots that need attention. - Adaptive Brightness

Smart lighting systems use sensors to monitor ambient light levels and adjust brightness accordingly. For example, areas that experience natural daylight can reduce artificial lighting during the day while maintaining optimal illumination at night. This adaptability ensures that workers always have adequate lighting without over-illuminating spaces, which can lead to glare and eye strain. - Motion-Activated Lighting

Motion sensors can detect activity in real-time, automatically illuminating areas as workers move through them. This not only conserves energy but also ensures that no area remains in darkness, especially in spaces that are not frequently accessed, such as storage rooms or infrequently used aisles.

Boosting Productivity

In addition to enhancing safety, intelligent lighting solutions have a significant impact on productivity. By creating an environment where workers can perform tasks more efficiently and comfortably, businesses can unlock higher levels of output and operational efficiency.

- Optimized Light for Task-Specific Needs

Different industrial tasks require varying levels of light. For example, precision assembly lines may require higher brightness and color accuracy compared to loading docks. Intelligent LED lighting systems allow businesses to tailor illumination levels for specific tasks or zones, ensuring that workers always have the optimal lighting conditions. - Reduction in Fatigue and Errors

Poor lighting can cause eye strain and fatigue, leading to a decline in worker performance and an increase in errors. Better lighting conditions also contribute to a reduction in mistakes, boosting overall productivity. - Remote and Automated Control

Intelligent lighting systems often come equipped with IoT-enabled controls, allowing facility managers to program and automate lighting schedules. This ensures optimal lighting conditions with minimal manual intervention. Through centralized dashboards, managers can monitor performance, identify inefficiencies, and make real-time adjustments to improve productivity.

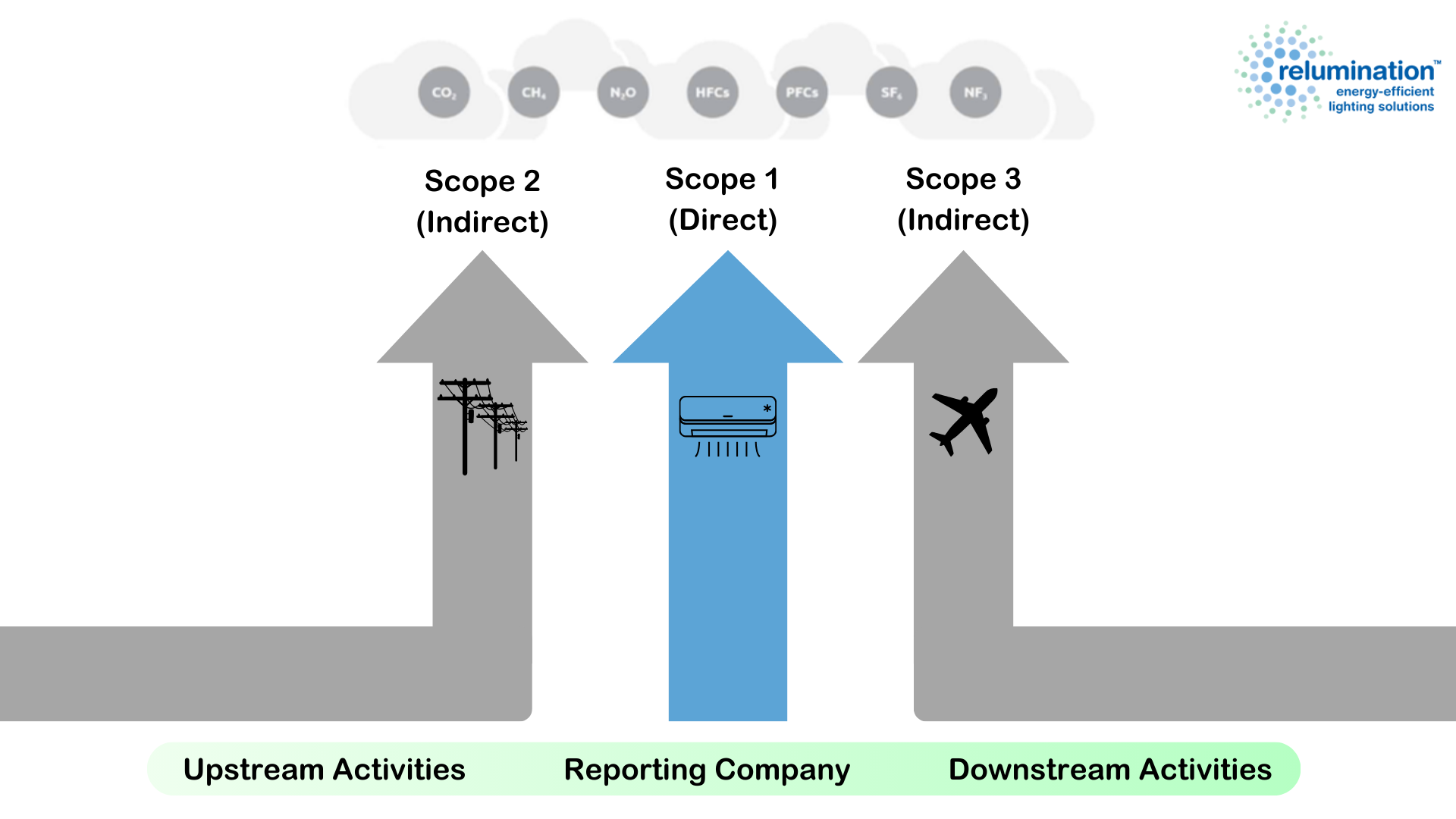

Energy Savings: The Added Bonus

Beyond safety and productivity, intelligent lighting systems also deliver substantial energy savings, making them an worthwhile investment. LED technology consumes significantly less energy than traditional lighting systems, and smart controls further enhance efficiency by reducing unnecessary usage. Features such as daylight harvesting, motion detection, and zone-specific lighting ensure that energy is only used where and when it is needed. This not only reduces utility bills but also contributes to a lower carbon footprint, aligning with sustainability goals.

Case Study: Transforming a Distribution Center with Smart Lighting

Consider a large-scale distribution center that recently upgraded to an intelligent lighting system. By replacing traditionally used fluorescent lighting with updated LED fixtures equipped with smart controls, one of our client’s achieved:

- A 88% reduction in energy consumption annually.

- Improved worker visibility and safety.

- Remote monitoring capabilities, enabling quick adjustments to lighting schedules so you are aware of your facility’s activity.

Learn more about this facility here.

A Smart Investment for Your Business Operations

As industrial facilities strive to remain competitive and uphold sustainability standards, the adoption of intelligent lighting solutions is no longer a luxury—it’s a must-have. By enhancing safety, improving productivity, and delivering energy savings, these systems pay for themselves in as little as 2 years.

Whether it’s a warehouse, manufacturing facility, or distribution center, upgrading to smart LED lighting is a step toward a brighter, safer, and more efficient future. With turnkey providers like Relumination, the transition has never been more seamless. Redefine what energy usage looks like in your facility. Contact us today for a free lighting consultation.